Accessories

Seal Welded Nuts

Seal Welded Nuts may be added to virtually any frame style to allow “Bolt-to-Duct” installation. PAPCO can provide a bolt pattern or work to your drawing/specification. Seal welded nuts can allow easier installation and removal of the expansion joint without the need to weld.

Fly Ash Seal

For select systems a fully installed and secured fly ash seal may be required. PAPCO’s fly ash seals are manufactured from tightly woven cloth and wire mesh fabrics. The fly ash seal is a fabric membrane that spans between the baffle plate (flow liner) and frame. The fly ash seal prevents fine particulate from filling the cavity that is formed between the expansion joint frame halves. PAPCO’s fly ash seals are uniquely robust and superior in construction. Instead of the loosely installed membranes that are common to the industry, PAPCO’s fly ash seals are attached to the joint’s frame by means of 3/8˝ welded studs on 3˝ centers. The fly ash seal is then secured using a 1-1/2˝ wide x 1/4˝ thick backing bar. It is in effect, a joint within a joint. Fly ash seals can be made from various cloths including but not limited to: vermiculite, aluminized, coated cloths (with or without) a knitted alloy mesh cover.

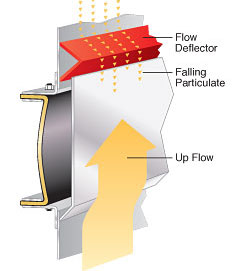

Flow Deflectors

Flow deflectors are required for vertical flow up and angle up flow applications where fly-ash or other particulate is present. The flow deflector (shown in red) will prevent particulate from falling back down the duct and filling the expansion joint cavity. Depending on the style of the expansion joint, the flow deflectors may be an integral part of the frame or shipped loose.

Splicing Irons & Consumables

PAPCO offers the special tools required to splice or patch our expansion joints. Our standard splice kits include PFA splicing film only. We offer hot splicing irons (sold individually or as part of a professional splicing kit). We also offer cold splice compounds for elastomer and fluoroelastomers. PAPCO technicians can also be dispatched to perform splicing and patching services.

Lifting Lugs / Retaining Bars

All expansion joints are shipped with a suitable quantity of lifting lugs and/or retaining bars. Retaining bars are fixed across the face of the expansion joint to keep the joint from expanding, compressing, or moving laterally during shipping and handling. Retaining bars must be removed prior to start-up. For larger joints, additional lifting lugs may be required. PAPCO will include the needed quantity of lifting lugs to be used at the most logical points or as specified by the customer

Drain Kit

PAPCO can supply drain fittings for expansion joints located in wet areas such as the absorber outlets and stack inlets of flue gas desulphurization systems. These drains are typically located at the bottom center and are connected to flexible drain hoses to allow the expansion joint to cycle through its full range of movements. These drains can be supplied in PTFE, steel, stainless steel, Hastelloy®, and various other materials.