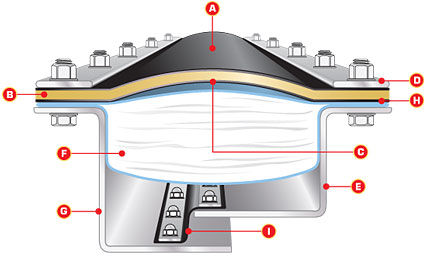

A = Structural Gas Ply

B = Thermal Barrier/Insulation Matting

C = Retaining Ply

D = Backing Bars

E = Baffle Liner

F = Insulation/Accumulation Pillow

G = Frames

H = Gasket

I = Fly Ash Seal

A. Structural Gas Ply

The structural gas ply is the outermost layer of the expansion joint belt (Flexible Element). It is 100% nonporous, features a high tensil strength, and allows movement in all directions. The structural gas ply is designed to withstand the system temperature and be resistant to chemical attack from inside and out. Based on system temperatures, the Structural Gas Ply may stand alone or be combined with additional thermal barriers to form a composite belt. PAPCO offers Structural Gas Plies of various combinations of EPDM, Fluoroelastomer (FKM), and PTFE. Expansion joint belts are available as Flat Belt or U-Shaped “Integrally Flanged” varieties.

B. Thermal Barrier/Insulation Matting

The Thermal Barrier Layer ensures that the temperature of the inside surface of the Structural Gas Ply does not exceed its maximum operating temperature. This layer (in combination with a secondary gas/vapor ply) also reduces the chance of hot flue gas condensing on the inside of an uninsulated Structural Gas Ply. Unless otherwise specified PAPCO uses only the highest quality 11# Density Mechanically Bonded Fiberglass or Ceramic Needle Mat insulation.

C. Retaining Ply

The Retaining Ply is designed to join the Structural Gas Ply and thermal barrier. It protects the thermal barrier from mechanical damage and provides additional thermal protection. The retaining ply is selected based on the operating temperature and chemical compatibility. PAPCO frequently uses high strength tightly woven fiberglass cloth, silica cloth, vermiculite coated cloths, aluminized fabrics and/or alloy wire mesh in various combinations.

D. Backing Bars

Backing bars are used to seal the flexible element against the frame. PAPCO designs the backing bars in accordance with FSA (Fluid Sealing Association) standards but always ensures that the thickness, width, fastener size, and spacing are sufficient for the system pressure to meet FSA standards. PAPCO’s standard specification calls for a 2” x 3/8˝ backing bar with rounded edges to protect the flexible element. The bars feature slotted holes for easy fit up and adjustment. PAPCO includes 1/2˝ hardware spaced 4˝ on center as a minimum or as specified by the customer.

E. Baffle Liner

The baffle liner will redirect airflow over the expansion joint cavity and protect the expansion joint’s flexible element and insulation/accumulation pillow from fly ash accumulation, flutter, and abrasion. It will also serve to deflect heat. Baffle liners should cover the full perimeter and width of the expansion joint so that the cavity is covered at all times. The material type and thickness of the baffle liner should be

reviewed by the buyer’s engineer for suitability. Baffles are either an

integral part of the expansion joint frame or they can be shipped

loose. The many styles of baffle liner which offer different benefits

should be discussed when designing an expansion joint.

Learn More...

F. Insulation/Accumulation Pillow

Insulation and accumulation pillows are used to protect the flexible

element from the system’s heat and prevent fly ash from filling the

expansion joint cavity. The insulation/ accumulation pillow is comprised

of layers of high density mechanically bonded thermal blankets

wrapped in a high strength case designed to meet the system’s

conditions. The pillow is secured to the frame underneath the belt with

tabs; by welded pins with speed washers; or other unique methods.

Attaching the pillow to the frame sides ensures that the pillow stays in

the proper position after the joint has moved axially or laterally. Without

such a feature, the pillow would become compressed and not “spring

back” to cover the entire width of the expansion joint cavity allowing

hot gas and/or fly ash penetration.

Learn More...

G. Frames

Also called flanges in some instances, they comprise the metallic

portion of a non-metallic expansion joint. Frames allow the fabric

expansion joint and its components to be easily attached to the duct

by either welding or bolting. The frame provides a standoff between

the duct and the belt to aid in heat dissipation and passive cooling.

It forms a cavity where the pillow can be installed. There are almost

endless lists of frame styles which may include integral baffle liners.

Learn More...

H. Gasket

Single layer flexible elements like PAPCO’s 500SL TEXFLEX® and flexible elements for special applications require a sealing gasket where they are bolted to the frame. PAPCO typically uses a chemical resistant PTFE dipped ladder gasket but other elastomers, fluoroplastic, and fluoroelastomers are available.

I. Fly Ash Seal

For select systems a fully installed and secured fly ash seal may be required. PAPCO’s fly ash seals are manufactured from tightly woven cloth and wire mesh fabrics. The fly ash seal is a fabric membrane that spans between the baffle plate (flow liner) and frame. The fly ash seal prevents fine particulate from filling the cavity that is formed between the expansion joint frame halves. PAPCO’s fly ash seals are uniquely robust and superior in construction. Instead of the loosely installed membranes that are common to the industry, PAPCO’s fly ash seals are attached to the joint’s frame by means of 3/8˝ welded studs on 3˝ centers. The fly ash seal is then secured using a 1-1/2˝ wide x 1/4˝ thick backing bar. It is in effect a joint within a joint.