Baffle Liners

Baffle Liners

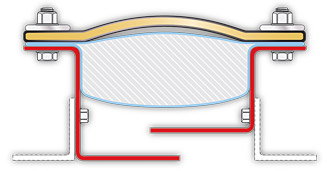

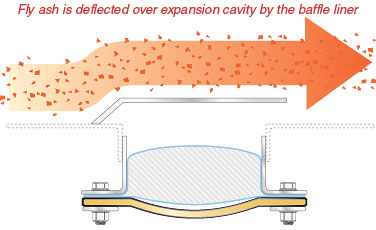

The baffle liner will redirect airflow over the expansion joint cavity and protect the expansion joint’s flexible element and insulation/accumulation pillow from fly ash accumulation, flutter, and abrasion. It will also serve to deflect heat. Baffle liners should enclose the full perimeter and width of the expansion joint so that the cavity is covered at all times. The material type and thickness of the baffle liner should be reviewed by the engineer for suitability. Baffles are either an integral part of the expansion joint frame or they can be shipped loose. The many styles of baffle liner which offer different benefits should be considered when designing an expansion joint.

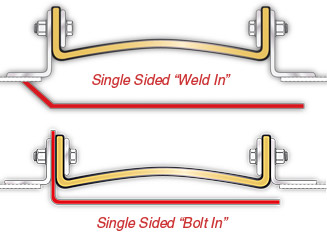

Single Sided Baffles

Single sided baffles are welded or bolted to the upstream side of the expansion joint and extend across the full width of the breech. Single sided baffles are generally field welded to the duct or bolted to the upstream mating flange. Single sided baffles also typically have a single bend and extend into the duct by an amount equal to the lateral movement plus 1˝.

Double Overlapping Baffles

Double overlapping baffles are factory welded (integral) to the expansion joint frame and over the full width of the breech without extending past the downstream mating flange. Double overlapping baffle liners can also be designed so that they do not protrude into the duct and reduce flow. Integral double overlapping baffles are a standard feature on Z-Frames but also can be included on J-Frames and Channel Frames.