U-Shaped & Specialty Joints

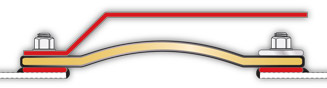

U-Shaped (Integrally Flanged) Joint

U-Shaped Expansion Joints feature integrally molded flanges that allow them to be bolted directly to existing duct mating flanges. In most cases these integrally molded flanges eliminate the need for frames. PAPCO innovated a procedure and the equipment necessary for the molding of continuous-corners in U-shaped expansion joints. PAPCO currently has eight fully automated corner molding machines in operation. The automated machinery, along with a perfected technique, produces the finest integrally molded corners in the industry.

Economy Clamp Type Joint

These joints are a simple combination of an endless belt and off-the-shelf clamp, for low pressure applications only. The belt is mounted directly to a duct or pipe and affixed with the clamp provided.

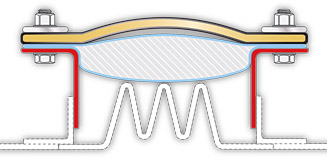

Internal Wrap Expansion Joint

Internal Wrap Expansion Joints are useful for applications where there is limited access or space to install a “traditional” belt-over-frame type expansion joint. However, careful attention must be paid to the material selection since there is no ambient cooling. Internal wrap joints can be installed from inside the duct minimizing scaffolding requirements. These joints can often be installed without removing the old, failed expansion joint. Internal Wrap Expansion Joints use “stud bars” welded to the inside of the duct wall to mount the belt, and usually include bolt-on baffle liners.

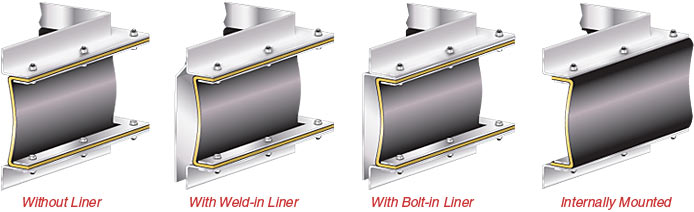

Fabric Over Metallic Expansion Joint Replacment

This design allows for the quick and inexpensive means to replace existing metallic expansion joints. A simple ~Angle-Style~ or ~Channel-Style~ Frame with a non-metallic flexible element [belt] is fitted over and around the existing metallic expansion joint. These expansion joints can be installed without removing the old leaking metal bellows and in some cases while the unit is still in service. To minimize labor costs these joints are typically shipped in assembled halves ~C-Sections~ so they can be easily fit over the outside of the duct. Options include insulation pillows and internal baffle liners which may be required for the application.