Insulation Pillows

Insulation and accumulation pillows are used to protect the flexible element from

the system’s heat and prevent fly ash from filling the expansion joint cavity. The insulation/ accumulation pillow is comprised of multiple layers of high density

mechanically bonded thermal blankets wrapped in a high strength cloth and/or

alloy cases designed to meet the system’s conditions. The pillow is secured to

the frame underneath the belt with tabs or by welded pins with speed washers

(or other unique methods). Attaching the pillow to the frame sides ensures that

the pillow stays in the proper position after the joint has moved axially or

laterally. Without such a feature, the pillow would become compressed

and not cover the entire width of the expansion joint cavity, allowing hot gas and/

or fly ash penetration. Pillows can be used with

Insulation and accumulation pillows are used to protect the flexible element from

the system’s heat and prevent fly ash from filling the expansion joint cavity. The insulation/ accumulation pillow is comprised of multiple layers of high density

mechanically bonded thermal blankets wrapped in a high strength cloth and/or

alloy cases designed to meet the system’s conditions. The pillow is secured to

the frame underneath the belt with tabs or by welded pins with speed washers

(or other unique methods). Attaching the pillow to the frame sides ensures that

the pillow stays in the proper position after the joint has moved axially or

laterally. Without such a feature, the pillow would become compressed

and not cover the entire width of the expansion joint cavity, allowing hot gas and/

or fly ash penetration. Pillows can be used with

Flat Belts or U-Shaped varieties.

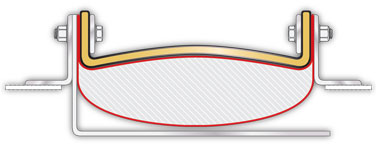

Tabbed Pillow

A tabbed insulation pillow is comprised of mechanically bonded insulation blankets wrapped in a cloth/alloy case. The pillow’s integral flanges are bolted in place underneath the flexible element and backing bars. This method of attaching the pillow to the frame sides ensures that the pillow stays in the proper position, up against the belt, to provide the belt with the highest degree of thermal protection. Without such a feature, the pillow would sit loosely within the expansion joint cavity and could allow hot gas and/or fly ash< to come in contact with the flexible element.

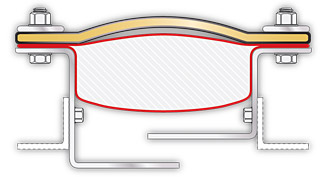

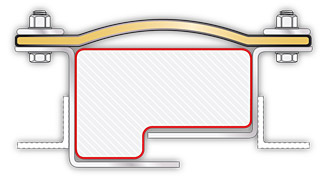

Pinned Pillow

A U-shaped insulation pillow is comprised of mechanically bonded insulation blankets wrapped in a cloth/alloy case. The pillow is formed into a U and secured to the expansion joint frame by means of welded pins and speed washers. This method of attaching the pillow to the frame sides ensures that the pillow stays in the proper position after the joint has moved axially or laterally. Without such a feature, the pillow would become compressed and not cover the entire width of the expansion joint cavity, allowing hot gas and/or fly ash penetration.

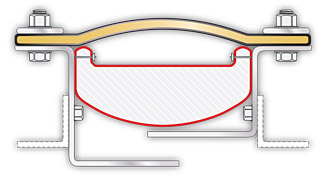

Block Pillow

A pillow block insulation pillow is comprised of mechanically bonded insulation blankets wrapped in a cloth/alloy case. This pillow design fills the expansion joint’s cavity with a large protective mass. Pillow blocks can be easily installed or replaced during an outage.

Typical materials used in the construction of insulation pillows include:

Internal Matting

- 11# density mechanically bonded type “E” fiberglass needle mat (Temperatures up to 1000°F)

- High density mechanically bonded ceramic needle mat (Temperature >1000°F)

External Case Covers

- 18 oz., 24 oz., and 32 oz. unique tightly woven fiberglass and vermiculite coated cloth

- Aluminum coated (aluminized) or aluminum laminated fiberglass cloth

- Silica cloth (Temperature >1000°F)

- Knitted stainless steel, Inconel® or other alloy – wire mesh can be used with these materials

- Aramid/Kevlar® blended fabrics